GreenStart's mission is to foster a resilient energy and food system for New Hampshire by providing technical education and practical agricultural examples. An educational non-profit organization established in 2006, GreenStart sees food and fuel security as the end-product of a vibrant, sustainable agriculture system in New Hampshire.

New Hampshire has 40% of its land area in agricultural soils, yet farms only 10% and imports 95% of its food and fuel. New Hampshire has no significant petroleum resources. To feed and fuel itself from sustainable natural resources, New Hampshire must improve its soils while also improving production.

To achieve this end, GreenStart facilitates projects that

1) increase soil carbon “banking”

2) decrease energy inputs

3) increase both food and fuel outputs (positive energy and carbon balance)

4) promote “tight” cycling of nutrients

5) provide opensource access to appropriate knowledge, seeds and equipment

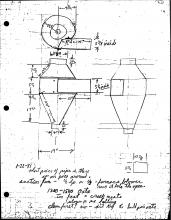

I will try and add more to the the wiki later - but your description is pretty accurate. The vanes in the rotor spin the seeds out where they hit the stator (stationary ring. The hull is knocked off by the impact. In some impact dehullers I have seen, the stator is a stone like material, but the one documented here used a steel ring.

The seed/grotes and hulls are blown/expelled by the air movement caused by the rotation of the fins on the side of the rotor. The cyclone separator is designed to have a vacuum on the top to separate/winnow out the hulls and have the heavier seed drop down for collection. Alternatively the mixture can be collected and run through a fanning mill (which I will be documenting later this spring). A fanning mill screens for over and under size and separates by weight.

To hull barley or spelt more velocity is needed and a higher rotational speed. Hammers/impellers are also added to the rotor and a correctly sized screen is substituted for the stationary ring such that the hulled grain can be expelled, but the unhulled grain is beat up further until it is able to exit through the screens. I do not yet have any drawings of this feature.

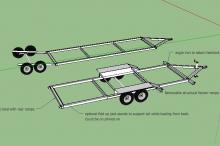

It will be great to have this design into autodesk inventor. I hope that the sketchup drawings are helpful as a start. It needs some cleanup but I can save it in another format like 3ds for importing if it would be useful. My hope is that we can post machine files here too if you use a torch table or water jet etc. for cutting any of the pieces.