GreenStart's mission is to foster a resilient energy and food system for New Hampshire by providing technical education and practical agricultural examples. An educational non-profit organization established in 2006, GreenStart sees food and fuel security as the end-product of a vibrant, sustainable agriculture system in New Hampshire.

New Hampshire has 40% of its land area in agricultural soils, yet farms only 10% and imports 95% of its food and fuel. New Hampshire has no significant petroleum resources. To feed and fuel itself from sustainable natural resources, New Hampshire must improve its soils while also improving production.

To achieve this end, GreenStart facilitates projects that

1) increase soil carbon “banking”

2) decrease energy inputs

3) increase both food and fuel outputs (positive energy and carbon balance)

4) promote “tight” cycling of nutrients

5) provide opensource access to appropriate knowledge, seeds and equipment

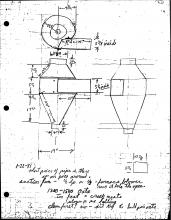

My understanding is that the screen size is very important so that after the dehulling process both the hull and the grain are able to fall or push through the screen and then are carried by the air flow up and out of the housing to the cyclone separator. There are details about the vacuum setup in the engineering drawings and notes posted. I think it was 2000cf/min and a 2hp suction fan.

My understanding is that even with the large commercial systems the process is fairly manual for re-running unhulled grains - and requires some fine tuning and attention to varying crop conditions. larger capacity seed cleaners and number of screens both prior to and after hulling will help reduce the labor of the process to get a quality finished product and reduce loss. Like with most of this kind of processing sizing and sorting for consistency helps prior to processing. That is why I think the fanning mill is so important.