GreenStart's mission is to foster a resilient energy and food system for New Hampshire by providing technical education and practical agricultural examples. An educational non-profit organization established in 2006, GreenStart sees food and fuel security as the end-product of a vibrant, sustainable agriculture system in New Hampshire.

New Hampshire has 40% of its land area in agricultural soils, yet farms only 10% and imports 95% of its food and fuel. New Hampshire has no significant petroleum resources. To feed and fuel itself from sustainable natural resources, New Hampshire must improve its soils while also improving production.

To achieve this end, GreenStart facilitates projects that

1) increase soil carbon “banking”

2) decrease energy inputs

3) increase both food and fuel outputs (positive energy and carbon balance)

4) promote “tight” cycling of nutrients

5) provide opensource access to appropriate knowledge, seeds and equipment

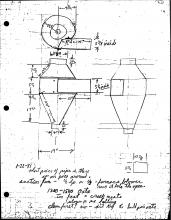

I would recommend taking the design documents to a local fabrication shop to get a quote. For barley you will want the hammer design modification for sure (rather than the impact huller design which is fine for oats etc.). The second stage of winnowing the hulls and cleaning the seed is also important to consider. A clipper seed cleaner properly set up can get you most of the way there. I expect it could all be built for less than $2000. If a fabricator gets setup to do a small production run of kits, the cost could be substantially less. If you do build a version, please post your results and costs!