Introduction

Hops are commonly harvested at 75-80% moisture by weight, but are ideally pelleted, packaged and stored only after they are dried to 8-10% moisture. To put this into perspective consider that a pound of “dry” hops starts out with about 3 pounds of water (a little less than a half gallon) that has to be evaporated by drying.

In large, commercial hop production whole buildings are dedicated to the careful process of drying hops to the desired storage moisture. Given the nascent, distributed, and small-scale nature of Vermont’s resurging hop industry a different approach is needed. To this end, a modular hops oast has been developed and demonstrated by UVM Extension and Borderview Farm. This oast is designed as an integrated cabinet drier that holds trays of hops. The drying is accomplished with a fan, heater and controller.

Design

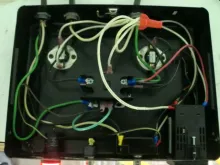

The aim of the design is to use readily available materials and common construction skills and to result in a modular and scalable oast that supports hop growers of various scales. A base module of 4’ W x 4’ D x 8’ H makes use of standard building materials well and allows for conveniently sized hop trays. All of the main structure is made with standard construction lumber and plywood. The electrical system is 220 VAC single phase and uses fairly common parts and wiring. The fan motor is 1/4 hP and the fan impeller is a 24 inch vane axial design capable of 3250 CFM at 0.7 iwc pressure rise (at 1750 RPM). The majority of air flow is circulation within the cabinet, however in order to dry the hops the humidified air must be removed. Holes are drilled in the top of the cabinet at high pressure and low pressure areas along the impeller resulting in exhaust and fresh air intake respectively. The placement of these holes and the degree to which they are open or covered determines how much “stripping” air is pulled through the cabinet. The heating element is a 3500 Watt bent tubular heater. Although one can dry hops using unheated, ambient air, the addition of well controlled heat to the air allows for quicker drying reducing labor and maintaining higher quality hops. The components used in this oast have been selected to dry 300 lbs of wet hops from 80% moisture to 10% moisture in 8 hours with little to no labor required.

A proportional-integral-derivative (PID) controller has been used in this system. This type of controller allows the user to set a target temperature and by monitoring the actual temperature in the cabinet using a thermocouple it “zeroes” in on the set-point. This differs from a thermostatic control which would provide an “average” temperature of the set-point but with sometimes wide fluctuations above or below it. The PID controller is always monitoring the difference between the set-point and the actual temperature, the historical difference, and the rate at which this difference is changing in order to predictably adjust the heater operation to attain the desired temperature.

A project of University of Vermont Extension; Vermont Agency of Agriculture, Food and Markets; and Massachusetts Department of Agricultural Resources through the USDA Specialty Crops Block Grants Program.

A NOTE ON THE MOTOR: We used a salvaged motor from a Blodgett Pizza Oven. It was namplated as an AO Smith Century AC motor, P/N 8-187739-02, 0.75/0.21 hP, 2 speed 1725/1140 RPM, 115 VAC single phase, drip proof enclosure, 56Z frame. It had a 5/8" OD x 4.5" L keyed shaft. In our case, the fan hub was mounted with a press fit keyed hub. I called Regal Beloit who handles the AO Smith Century Line now. They indicated that is an OEM motor and they have no direct substitutes. However, Grainger #2FGP9 looks like it could work in this application with some adjustment or fabrication of a mounting frame. http://www.grainger.com/product/CENTURY-Motor-2FGP9 There are probably other options with better frames. I just haven't been able to dig into it in great detail.

Comments

Window is a recent version