Search results

Search results

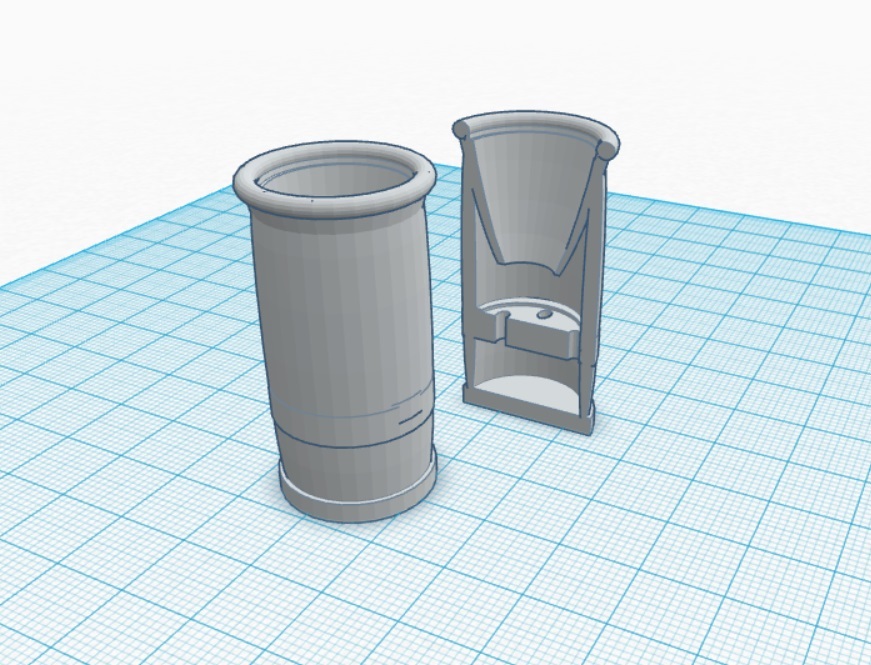

Food dryer

Left side tapering plenum contains downward blowing stove hood fan and heating element from toaster oven . Warmed air blows across 6 16 by 16 trays that are separated by upward sloping steel flashing baffles . Air is forced up through each tray and exits on right into upward expanding air exit. No moist air touches any other food. 1/4 inch through rods support flashing on the front and back .trays sit on top of flashing on right and bolts on the left side above baffle. Case was made from bits and pieces and could be made from washer /dryer/stove cases. I have made several much larger ones from insulated garage door panels . Have also used simple solar collector for heat.

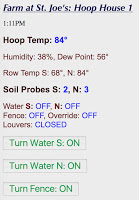

Hoophouse IoT & Temperature Control

49: IoT* for Farming & 56: Hoop House Temperature Control See my blog at http://dicks-photon-arduino.blogspot.com/ especially Posts 49 and 56

Seed Fractionator or Zigzag Seed Cleaner

A seed fractionator operates by subjecting seed to a tortuous air stream of finely adjustable speed. The seed sample is separated into light seed and heavy seed. The fractionation can be done several times to subdivide a sample into more parts. Germination tests performed on each sample allow the seed seller to certify the germination rate. This seed fractionator is powered by an electric shop vacuum, which supplies a steady flow of air. These plans were developed by Ben of the RealSeeds company in England, http://www.realseeds.co.uk/

Biochar pyroliser

A piece of equipment for making biochar, a soil enhancer and carbon sequestration

bikecart

bike cart and garden cart made out of salvaged bicycle parts

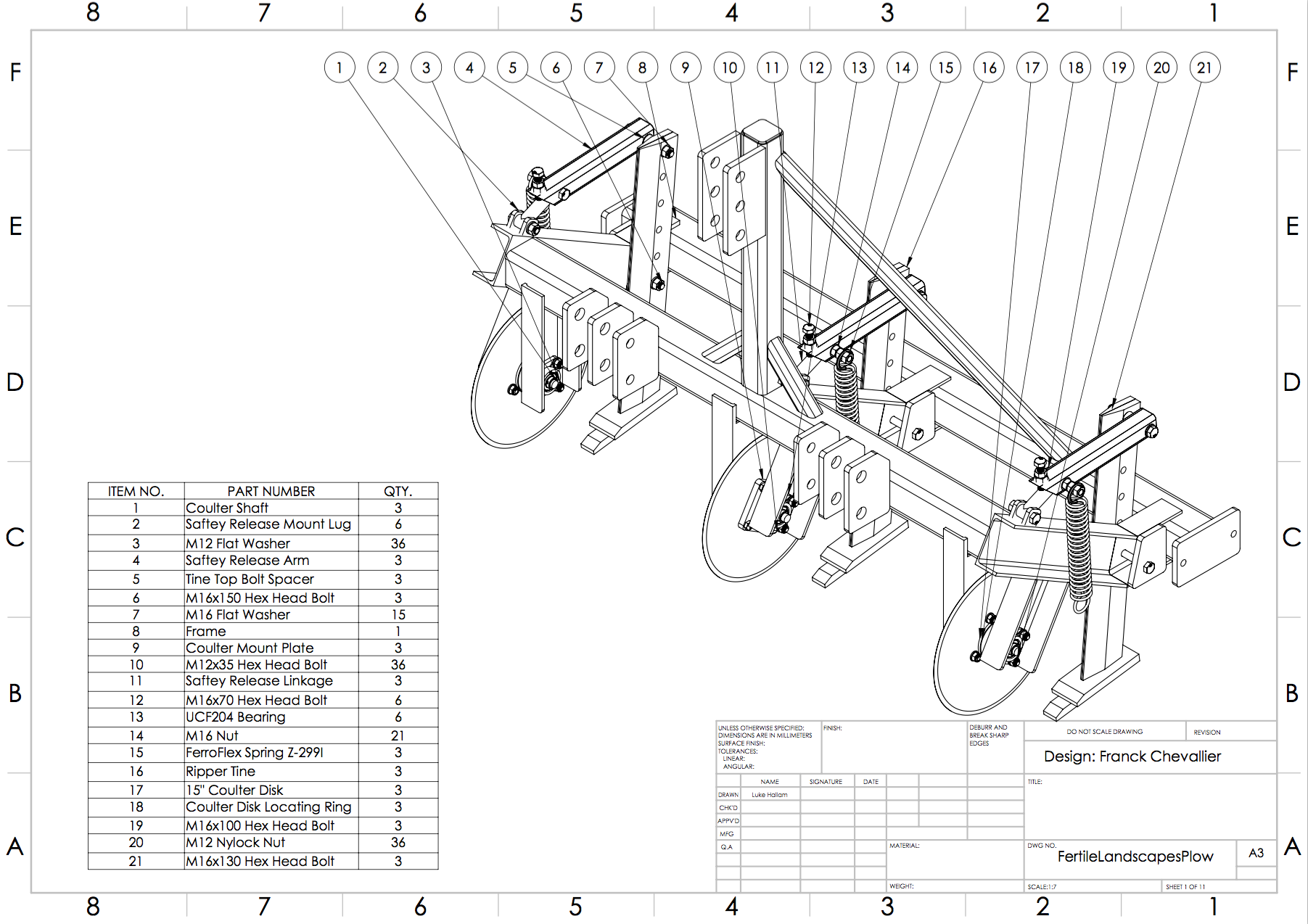

Fertile Landscapes Plow

Franck Chevallier has developed a open source subsoiler which is designed to be able to be built by local metal workers using readily available materials. In 2016 Regrarians' Darren J. Doherty instigated the formation of a working group to develop formal CAD plans to support Franck's effort and to further develop the #KeylineSuperPlow concept we've been working on since 2006/7. Luke Hallam came to the fore with the development of many CAD concept models and these are manifested in this set of working drawings. Luke and Franck have done a great service in doing this fantastic and unpaid work! The best feature of Franck's design is the very unique and effective shank break out mechanism. Its superior to any other system commercially available, with the exception of the very expensive hydraulic break out systems. The next step is to have the #KeylineSuperPlow concept go through a similar CAD process and this is now underway.

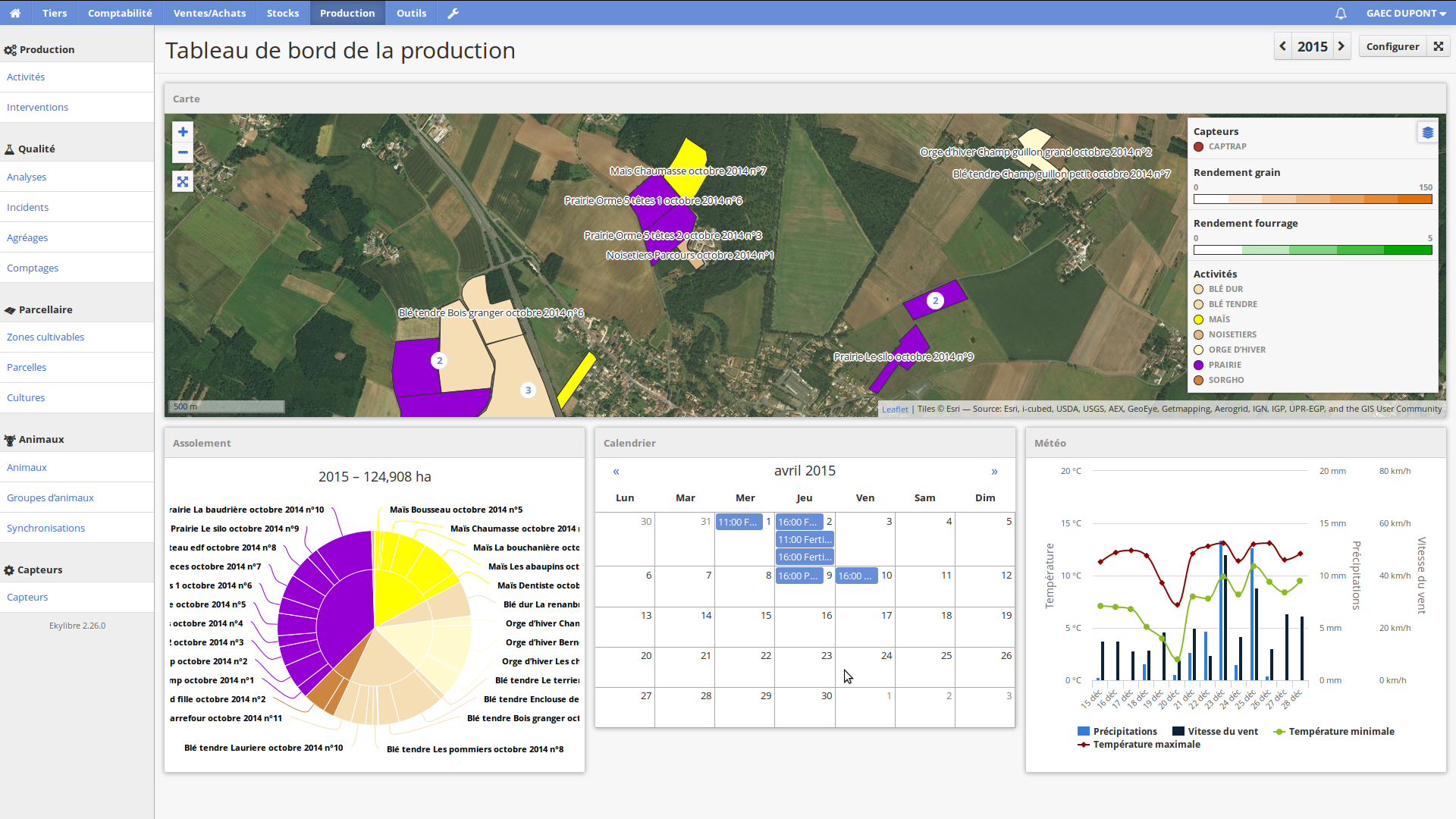

Open source FMIS

Ekylibre is an ERP to help farmer keeping all records in one place.

Bed lifter

Heavy Stirrup design using used municipal equipment cutting edge scrap...grader/plow blade. Requires a heavy frame to mount to 3-pt, and grader blade 'stirrup' must be specially welded to suit the high carbon alloy...usually 1070-1090 steel. Preheat, multiple passes with a low hydrogen rod such as 7018, 8018 11018, and post heat/slow cool. I use a milling machine to drill holes in the linking parts, and buy the pins at Tractor Supply, grade 8 bolts to attach the 'stirrup' at K.L. Jack. Category 1 or 2 setup. Best to lay out the height of the unit with careful measurements of the tractor's hitch movement to make sure you get the right depth. Also it seems to help the depth issue by angling the bottom blade of the 'stirrup' about 5 degrees to make it cut and drive itself deeper. Most farm tractors don't have down pressure ability, and the bed lifter can work its way out of the ground without some way to keep it engaged in the soil. My use of massive I beam 8 x 28# helps. Have not broken one yet in this rocky Maine soil. Units I've built have about 20 hrs labor and $50 in parts, mostly scavenged I beam 'drops' up to 4' wide. I've sold them, custom width and depth, for $300-$400 I have some Auto Cad drawings to share if you're interested.

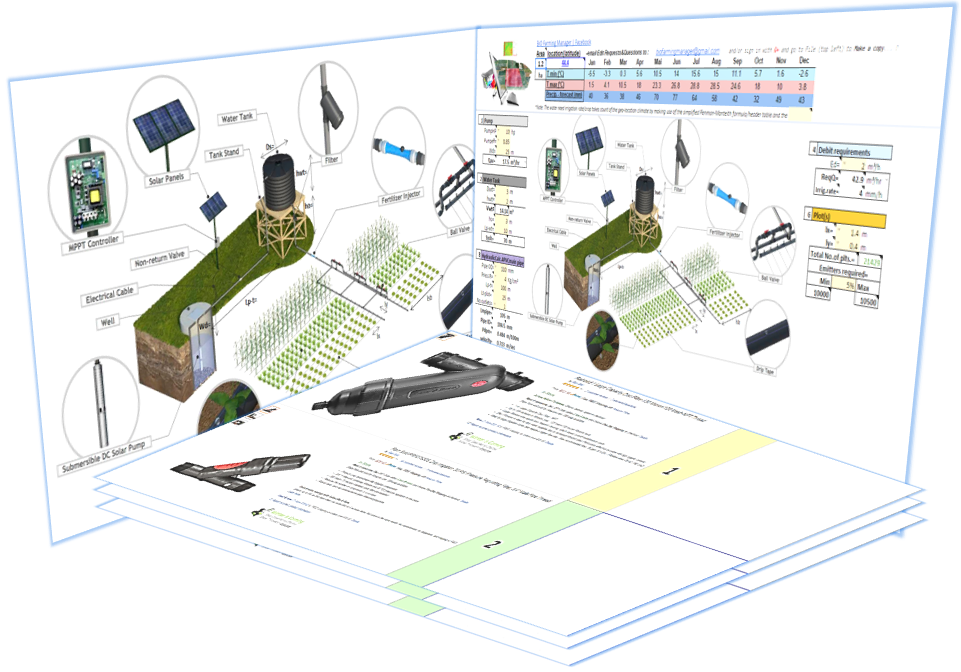

#IrrigationManager

Learn how to proper dimension your #irrigation system and water usage!

Slug Trap & Composter

PROBLEM: Slugs are damaging crops and farmers are trying to kill the slugs. We found a way to efficiently trap slugs without hurting them, so that farmers don’t have to worry about crop damage. SOLUTION: Our solution is eco-friendly, and harmless to all slugs used.The trap is created by recycled materials found in most households. For our slug trap we use a plastic water bottle. Slugs are attracted to the yeast at the bottom of the bottle, and they go into the trap. We have a barrier so they can’t fall and drown in the yeast. We recommend having a trap every twenty yards. You must dig a small hole and insert the bottle for use. We also recommend having the top of the trap at ground level. The slugs are then put into your compost. Slug can be used for composting because they are organic decomposers. Vermicomposting is using worms to aerate and help decompose compost, so in place of worms our slugs will digest raw or organic materials. When taking the composted material into the fields, we recommend checking the composted material to make sure there are no slugs inside of it. ***This prototype and solution were created in response to the research component of a robotics competition. Thirteen seventh graders in South Louisiana were challenged with finding an innovative solution to a problem with a way that humans and animals interact. The students initially found that slug slime had healing properties and wanted to find a way to capture slugs in farm plots and bottle the slug slime to sell at farmer's markets.