Need

A farm produced fuel that fits within crop rotations and provides for the flexibility and portability of diesel fuel, without the global infrastructure, while providing an energy balance that is similar or superior to draft power. The modular approach lends itself to easier open source modifications and iterations. The mobile approach enables a more flexible infrastructure. The cogeneration capability and on board air compressor enable the unit to operate as back up power for a farm operation as well as provide high volume shop air.

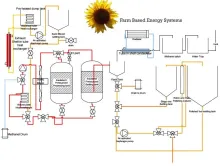

Functional description

The basic biodiesel process, transestrification, can be found here

The trailer modifications are documented on a separate wiki which will be linked here

Trailer is 8 bay(on each side) hinkly beverage type trailer set up with a fifth wheel dolly. It is of aluminum construction on a central steel frame. Each bay is connected to a central drain to contain spills. Each bay also is plumbed with air pressure and a vent line which leads to the methanol condenser and water trap.

The following skids and components make up the function of the the entire trailer. Each skid is designed with hydraulic type quick connects to facilitate easy removal and reduction in spills when attaching and detaching components. Each functional component will have its own tool wiki page

1)21kw 3 phase Cogeneration unit

2) 10 hp two stage air compressor and 120 gallon tanks

3) methoxide mix tank with stainless screen mixer and air operated pump Here

3) Initial gravity waste grease filtering

4)Exhaust preheat coolant loop, filter and stand pipe cone bottom tank with air operated pump

5)Insulated processing tank with static mixer and air operated pump Here

6)insulated holding tank air pressure evacuated

7)combined methanol flash tank and glyserol separation tank with stand pipe

8) polishing column with metered pump

9) final filter, stand pipe in cone bottom tank and air operated pump

10) methanol condenser, collection and water trap

11) oil and biodiesel testing laboratory table and tools

12) Arduino based data logger and temperature monitoring system Here

How to use the tool

(this would be the equivalent of an owners manual, pictures and video are excellent in this section)

Bill of materials and Sourcing

Bill of materials spreadsheet can be found here.

Construction/how to build

(this section should include basic step by step instructions and include supporting documentation like engineering drawings, CAD or CAM files, as well as supporting photos and videos)

Sketchup models of components are in progress

Next steps

Next steps for this project will be to:

1) begin documenting the bill of materials and numerous parts suppliers used for the project

2) collecting pictures and diagrams from the build process

3)setting up the individual component tool wikis and linking to them

4) documenting use of the processor and special features

5)measuring and drawing the universal and versatile skid construction

Market Place

(this section might link to fabricators of the tool or tool components who are members of the farm hack community)

This video shows some additional footage of the trailer and some of the design philosophy.

GreenStartNH constructed this unit and will assist with facilitating fabrication and assembly.