Moveable 16' X 48' Hoop house compatible with year-round vegetable growing rotations as described in "The Four Season Harvest" and elsewhere that is large enough to be useful but small enough to be constructed on farm with basic tools and easily sourced materials. Hoop house uses multiple independent wheel assemblies during moves that enable one or two persons to move the house manually.

Prototype created by Oxbow Farm

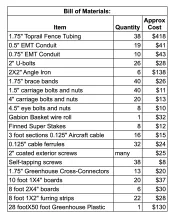

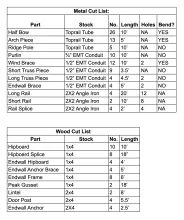

See the Bill of Materials and Cut List in the image gallery.

Vital Tools

- Drill Press for drilling holes in rails and brace pieces, I used a bench-top model and set it on the ground and used makeshift cribbing and the other pieces of angle iron to make a race to slide the rail being drilled.

- Metal cutting device, I used an angle grinder and abrasive cutoff wheels.

- Tubing Bender, I used the DY-12 bender from Lost Creek Greenhouse, the same or very similar bender is being produced by Lost Creek for Johnny’s and sold in their catalog. Usually Lost Creek has better shipping, it was free when I bought ours.

- Small Tubing Bender for bending the “Gothic Arch” ,this you have to DIY. I will try and get info about this up soon but there are better methods than the way we did it.

- Cordless Screwgun/Drill

- Rugged flat surface for bending hoops

- Flat surface for assembling hoops

- Hammer

- Heavy metal object with a flat surface to use as an anvil, an actual anvil would be awesome, a splitting wedge or splitting maul driven into a chunk of wood was what we used.

- Metal marking punch

- Drill bits

- 5/16ths ratchets and wrenches

Helpful Optional Tools

- Fencing Tool

- Vise-Grip pliers

- Ratcheting Box wrenches (these really sped things up when we bought a couple)

Also see the wiki for the independent wheel assemblies