NOTES FROM MEETING: The meeting focused on challenges with growing grains on the small scale. The first half of the day was spent learning about the workings of large scale combines, discussing the properties of heritage grain varieties, and reviewing demos of threshing and seed cleaning equipment. The main group then split into two groups to work on a design solution. Group 1 created a design for a thresher/winnower using a rotating drum from a combine in order to completely remove seed from plant material. Group 2 created a design for a small scale combine for a walk behind tractor that harvests and does a "rough" clean of the seed. The grain can then be cleaned further or used as is in animal feed.

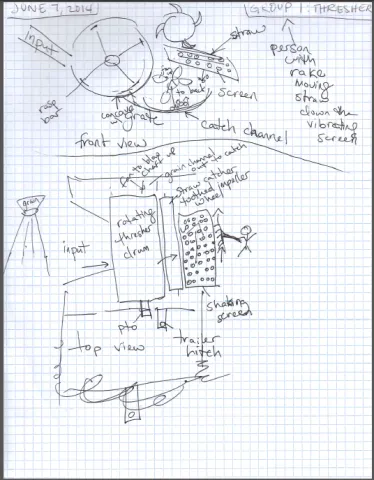

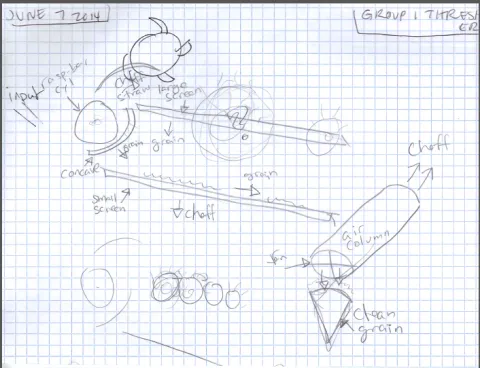

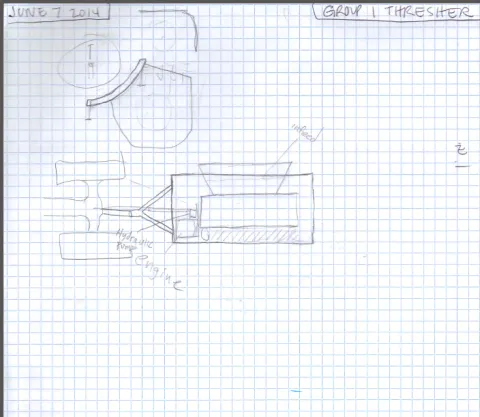

GROUP 1 NOTES ON DESIGN: Thresher/Winnower Starting Point: Grain or bean dry in field, cut or pulled and bundled Goal: Thresh and winnow to result in clean seed with minimal seed loss. Minimize transport of unthreshed grain. Allow for multiple power sources so no requirement for electricity in the field, electric option if in barn, PTO option. Maintenance and repair possible with reasonable mechanical skill. Assets: Rotation drum model- like idea of using same mechanism as combine with adjustable space between concave and rasp bar cylinder so we can operate in all crops (i.e. "laundry-wringer" style unit works on beans not on small grains). Primary threshing component concept and actual drum and rasp bars are existent.

Key design points: -Pull behind tractor with PTO power on trailer -Could be used in combination with reaper/binder for larger acreage or on a smaller scale with scythe and bundle -Grate in drum plus secondary capture and screen -Double screen concept with fan like antique seed cleaner. -Low angle works with vibrations -Interest to blow chaff opposite direction of seed and up so that chaff doesn't mix in final product

QUESTIONS: -How do we get the bulk of the grain which comes through grate, and the secondary captured screened grain into a hopper? Using gravity and shaking will the grain end up too close to the ground? -How do we get the straw to clear out of the system quickly enough to not jam up? -How much is cleaned by the primary threshing drum and how much is cleaned in the cleaning/separating elements of the combine? Found "Introduction to Agricultural Engineering Technology" discussion of the problem. They extensively treat efficiency of different elements but don't separate the thresher drum from the subsequent elements because there is no reliable way to tell. -As we struggle with handling straw that has some percentage of seed mixed in, we came to the idea of using our original thresher drum on a wagon with a person with a rake moving the straw along the vibrating screen up top. -Will the use of a scavenged thresher drum be too heavy-duty for simple framing? How small of a rasp bar can you find? -Need a gear box post PTO or post separate gas powered engine to get to the appropriate cylinder speed between 250-300 rpm.

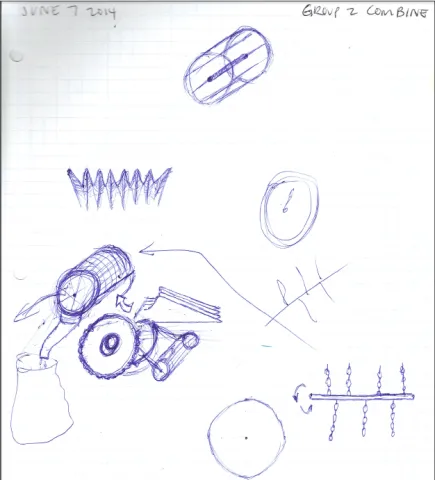

GROUP 2 NOTES ON DESIGN: Walk behind combine Goal: Harvesting, threshing, and cleaning seed to a point that is suitable for animal feed or could be further cleaned for consumption. -Equipment costs less than $3000. -Can cover 1-20 acres -Can function on 3% grade -50-60 bushel per acre capacity -hemp to bean range -pulled by Farmall type common tractor -Can harvest polyculture- a multi species cover crop for example

CONCERNS: -All harvesting processes machine not possible. Machine is based on scale and looking at the numbers, machine is already out there. Labor (what part is labor tedious) vs. Machine (in what part is it effective)

Farm Hack June 7, 2014 Resources

Slate: Going Against the Grain Small-scale grain farms are the next wave of the locavore movement. But can they actually make a profit?: http://www.slate.com/articles/life/food/2013/06/small_scale_grain_farmers_can_local_grains_be_profitable.html Designing a Small-Scale Grain Harvester: A Tool for Urban and Peri-urban Growers http://www.wpi.edu/Pubs/E-project/Available/E-project-042812-112952/unrestricted/Designing_a_Small-Scale_Grain_Harvester.pdf Fields of Seed: Small Scale Grain Harvesting Equipment: http://fieldsofseed.com/2013/10/29/small-scale-grain-harvesting-equipment/

Farm Scale Winnower: http://ltras.ucdavis.edu/files/Farm-scale%20winnower.pdf

Boaz Mini-Combine: http://www.eqmachinery.com/index.php

Threshers & Winnowers (videos): http://www.youtube.com/watch?v=U5P_pRkojfM&feature=player_detailpage

[http://www.youtube.com/watch?v=eIyMPe4Vsug&NR=1&feature=endscreen](http://www.youtube.com/watch?v=eIyMPe4Vsug&NR=1&feature=endscreen) [http://www.youtube.com/watch?v=1LQjGJ3P9pU](http://www.youtube.com/watch?v=1LQjGJ3P9pU) [http://www.youtube.com/watch?v=sr814GXHQIo](http://www.youtube.com/watch?v=sr814GXHQIo) [http://www.youtube.com/watch?v=vCku0Y9zFcA](http://www.youtube.com/watch?v=vCku0Y9zFcA) [http://www.youtube.com/watch?v=R7qschUGaY0](http://www.youtube.com/watch?v=R7qschUGaY0)