Problem addressed/functional need

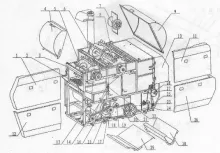

Small scale threshing and cleaning equipment is not easily available in the United States. Older combines have threshing cylinders that are often prone to plugging in weedy conditions - the axial flow design does not have "choke points" that are as vulnerable to plugging because the clearances and threshing area in general, is larger. This documentation is intended to spark new low cost approaches to small scale combine harvesting equipment. The other advantage is the potential for a smaller and lighter threshing and separating mechanism.

Functional Description and approach of small combine

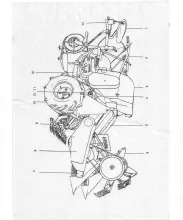

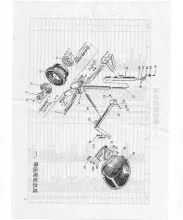

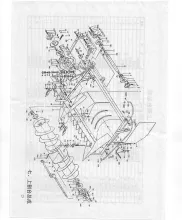

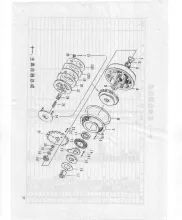

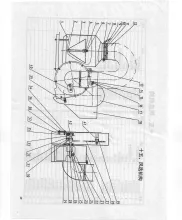

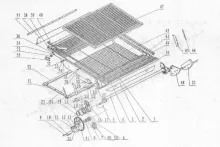

A cutter bar cuts the grain with a sicklebar mower which is fed by an auger to a feeder housing which carries the cut grain to the threshing chamber using serrated metal bars on rubber belting. The grain then enter the chamber where it is beaten by rotating bars and moved from one side of the chamber to the other by angled fins on the top of the chamber. The grain and smaller pieces of chaff fall through a partial cylindrical sieve set at a constant distance from the rotating bars. Weeds and larger straw are expelled at the end of the chamber. The grain and chaff falls to a tapered chamber to an auger which feeds it to an exit where the grain is moved by paddles to a cyclone separator with a manually damped vacuum applied to the top to extract chaff lighter than the grain and that is expelled through the vacuum fan. The grain movement from under the threshing chamber is also assisted by the vacuum generated through the vacuum generated on the cyclone. Grain is bagged and can then be run through a stationary seed cleaner before storage.

On similar larger machines, a more conventional sieve/chaffer fan separation process to either a bulk bin or manual bagger substitutes for the vacuum/cyclone separation process but because of the threshing system the need for straw walkers is eliminated.

recommended upgrades to current small model

-variable speed drives for cylinder speed and fan

-hydrostatic or variable belt drive for more precise ground speed adjustment

-replaceable spikes for more gentle threshing for crops like dry beans

-more robust feederhousing

-eliminate auger feeds with air flow to facilitate cleanout between crops and make for more gentle seed treatment

-specifications and source for burlap collection bags

Note A fanning mill should be considered a necessary part of this tool

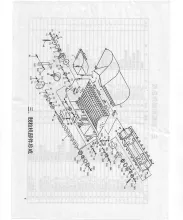

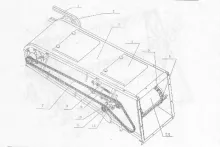

recommendations for larger tracked units

-design quick connect head for more versatility (draper, row crop or grain etc.)

-solution for breaking bridged grain in bin during unloading

-compressed air cleanout points for cleaning between crops and/or a full air system to replace augers for more gentle crop handling and ease of cleanout.

-replaceable spikes for different crops and conditions

-document screen dimensions in chaffer and sieve to facilitate custom order of screen material and more precise crop setups

-variable sized sprockets for fan and cylinder or variable speed belt drives to increase versatility

Tracked CombineHow to use the tool

(add video of the functioning components and adjustments and modifications that may be possible)

Construction/how to build

Bill of materials for domestically available bearings, sprockets, chain, belts, belting, keyed stock,mower bars, steel gauge and dimension, fan and cyclone substitutes, commercially available sieves and screen specifications

(please post in forums if there is interest in an assembly/build post for small scale commercially available combines)

Other activity

Open Source Ecology is working on a microcombine module which will "componentize" the functional units. Link for full documentation and OSE project management Microcombine

Identify standard dimensions, clearances, ratios and commonly available bearings, sprockets, chain, belts, belting, keyed stock,mower bars, steel gauge and dimension, fan and cyclone substitutes, commercially available sieves and screen specifications

Marketplace

The equipment for study was made made available by http://eqmachine.com

(https://web.archive.org/web/20130530201701/http://eqmachine.com/)

Ongoing projects

Open Source Ecology started a google doc to analyze the functional components - the link is here https://docs.google.com/drawings/d/1wmSIky7O_-MBX4JiLSSU7mVcBhWYNqBCIq87WPnVL4o/edit