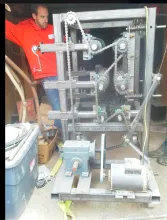

This ol' cracker was built to fulfill a need at VersaLand Farm. We grow a lot of garlic for our seed garlic business, and need an efficient way to break bulbs and clean cloves for planting. A skilled farmworker can break and clove around ~25lbs/hr. Hand-shelling 4,000+ lbs of seed garlic can quickly callous hands, spirits, and labor budgets. There had to be a better way.

Henry Ford once said, "If you need a machine and don't buy it, either way you're paying for it". Well spoken.

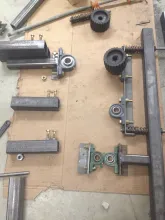

Components

- 2" & 2.5" 3/16" wall square tube.

- modified table rollers from a modern Lockwood potato digger (4 @ $130/ea) ---priciest component by far, well suited. green rollers in stage 1.

- 'wobble roller' wheels for a boat trailer $7/ea. 5" diam These were stacked over a keyed shaft for Stage 2.

- used valve springs from a diesel engine for 'oh shit a rock just went in the machine' protection lets the rollers push apart in the event of a large hard object.

- Boston Gear gear reducer 20:1, with a 3:1 pulley reduction (originally to build a mechnical bull) A 50:1 or 60:1 reducer would save some Rube Goldbergin'.

- 14' of 60 roller chain for main drive serpentine.

- 6' of 3/4" acme screw and nuts from http://surpluscenter.com

- 18' of 35 roller chain for parallel roller shaft adjustment screw

- Stage 3 'finger wheels' are Broekema star wheels from a sizing table. They're made in the Netherlands, but available in the US through potato equipment dealers. I used 70 Duro (hardness) 50 Duro may be a better choice.

Building

I drove 10 hours roundtrip to Lincoln, NE to visit the surpluscenter.com distribution warehouse and it was totally worth it. Get their catalog, even if its just to brainstorm. They have a treasure trove of quality stuff there at awesome prices, but their published shipping rates are a bit scary. Worth the drive for me. Helpful staff. Roller chain sprockets, keyed shafting, and random cool stuff are abundant and inexpensive there.

I built the first two stages with an 8% overdrive on one side to aid in a shearing action of the bulbs. One side had 13T sprockets, the other 14T.

Operation

Operating RPM of the shafts is ~38 RPM. Motor speed is 1725 RPM.

We dump a few bulbs into the hopper every few seconds, usually run 30lbs through and retrieve the rubbermaid tote below. Fans help clear bulb wrappers and chaff. A bit of table sorting afterwards can be done before planting. We could feed it a lot faster, but the chaff clears better at a reasonable flow rate.

This machine will crack and clean about 500lbs an hour at max capacity. Quite fun to run. Keep hands away from all moving parts.

Want to chat?, get in touch, farmhacking is best done with friends.