UVM Extension's Agricultural Engineering Program is dedicated to enhancing Vermont's food systems through education and outreach programs focused on analysis, design, evaluation and adoption of infrastructure, technology and equipment that meets the needs of food producers and processors.

Vermont's food systems are experiencing increased localization, value addition, diversification, extension of growing season and increased market demand. Farmers and processors with specific technical education needs and research and development ideas related to Vermont food systems are encouraged to contact us.

Hi Jenna and Louis,

Thanks for the feedback.

Arduino - Certainly could do this with an Arduino board. I opted for an off the shelf PID control, which available with a remote bulb thermocouple and solid state relay cost about the same as an Arduino Uno. The control portion of the BOM is EITHER a PID OR a thermostat, so you don't need both. The PID does the job very nicely, is quite versatile, and they have become quite inexpensive (less than a thermostat). They also have an auto-tune function which adjusts the PID tuning variables by algorithm. Makes life simple. And no additional programming or electronics labor was required. The benefit of the Arduino would be additional I/O, I suppose.

Relative Humidity Control - The PID in this system could take an RH sensor as input as well. My experience has been RH measurement in low temp and high humidity environments is not well done with generally available sensors. Louis and I have discussed this and I have been cooking something up here as a prototype that I think will help address this need.

Energy Use - Sorry, haven't measured electrical kWhr consumption yet. Fundamentally, this is no different from a conventional humidifier. The energy required is that needed to raise the temperature of incoming water to the setpoint and then to evaporate it into the air. Conventional humidifiers do this as well. The difference is a matter of evaporation (humidification) capacity and rate. This design allows for high rates of humidification which requires high rates of evaporation which requires greater energy input. But it can also do lower rates and I would expect the energy use to be comparable to other humidifiers. The only difference being, perhaps, greater heat loss through the surface area of the bucket. But I think that will be minor. My first attempt at this involved hacking an existing humidifier to try to make it simply auto-fill. They are actually pretty complex little machines. In that case, the reservoir was held by the machine at slight vacuum which made controlled auto-filling difficult even with a fancier fill valve.

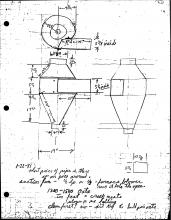

I also need to post a schematic and some build photos. 2nd generation build coming soon.