GreenStart's mission is to foster a resilient energy and food system for New Hampshire by providing technical education and practical agricultural examples. An educational non-profit organization established in 2006, GreenStart sees food and fuel security as the end-product of a vibrant, sustainable agriculture system in New Hampshire.

New Hampshire has 40% of its land area in agricultural soils, yet farms only 10% and imports 95% of its food and fuel. New Hampshire has no significant petroleum resources. To feed and fuel itself from sustainable natural resources, New Hampshire must improve its soils while also improving production.

To achieve this end, GreenStart facilitates projects that

1) increase soil carbon “banking”

2) decrease energy inputs

3) increase both food and fuel outputs (positive energy and carbon balance)

4) promote “tight” cycling of nutrients

5) provide opensource access to appropriate knowledge, seeds and equipment

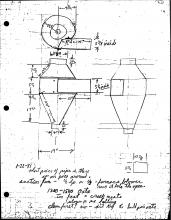

The unit we ran that was built on the plans is in Brattleborough Vermont. We had it here for the Farm Hack New Hampshire event and tested it on oats and It worked very well. We did not set up the cyclone separator but we used a clipper fanning mill to separate the chaff and we had a product which was clean enough to make oatmeal with. The raw footage is being sent to me next week which should show the unit running and working - but while I track that down I can post some still images I tool before we ran it. The images taken are inside the sheet metal housing mostly show the stator and cylinder with flat fan blades which create airflow to blow out hulled material. The stator blocks a good view of the gap between stator and cylinder. The other photo is of the gate to control flow into the huller.