Problem Statement/functional need On our small organic CSA farm, we harvest a lot of root veggies for storage in the fall. This is when we harvest the largest quantities, and when the water feels the coldest on the hands. We have been out washing carrots in just above freezing temps. Most of these root veggies end up in our cold room and we give out in our fall and winter baskets. We needed a more automated way to wash and sort our root veggies.

Functional Description/approach This is my basic barrel washer design and build. We built a barrel using rims from an old mountain bike. Then set that on 4 powered wheels. I originally planned to power this with a garage door opener (already turns slow, has a chain gear), but I learned (through trial) that the motor would not turn continuously and the plastic worm gear would not hold up to the abuse of carrot washing.

See the video on Vimeo Barrel Washer

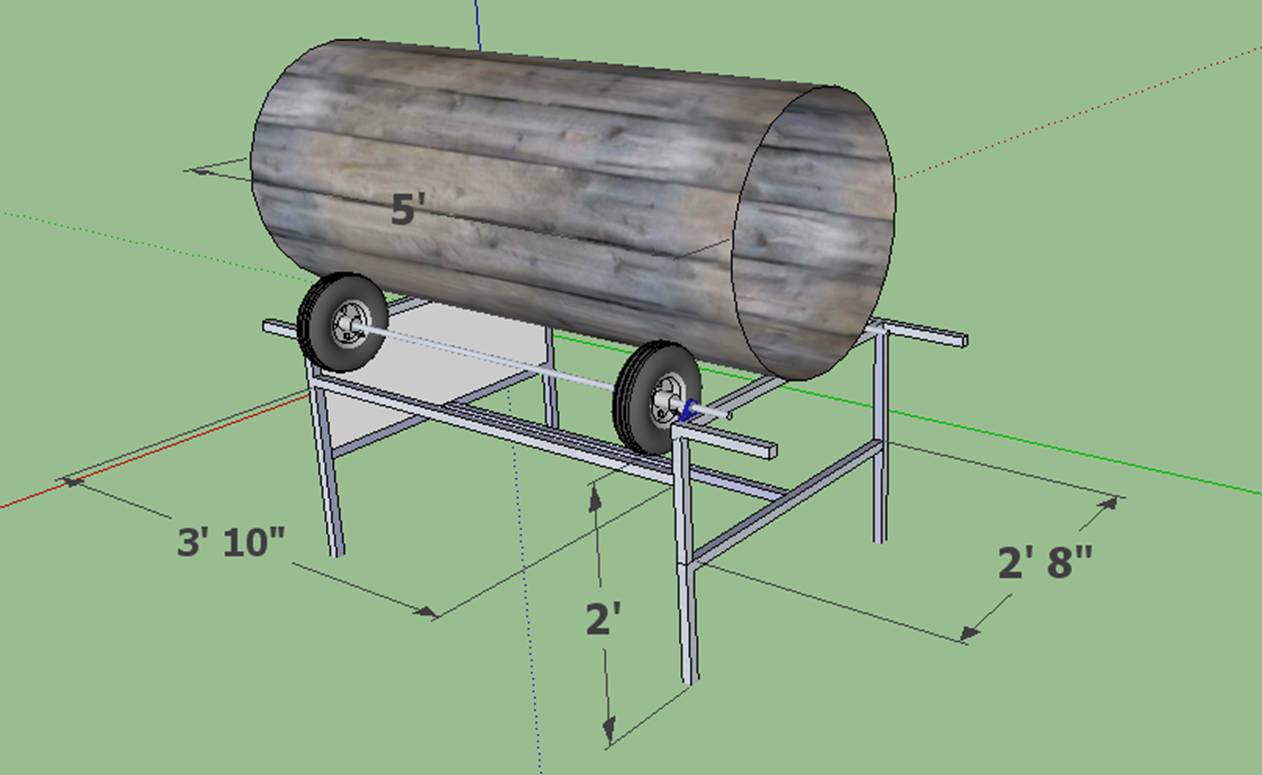

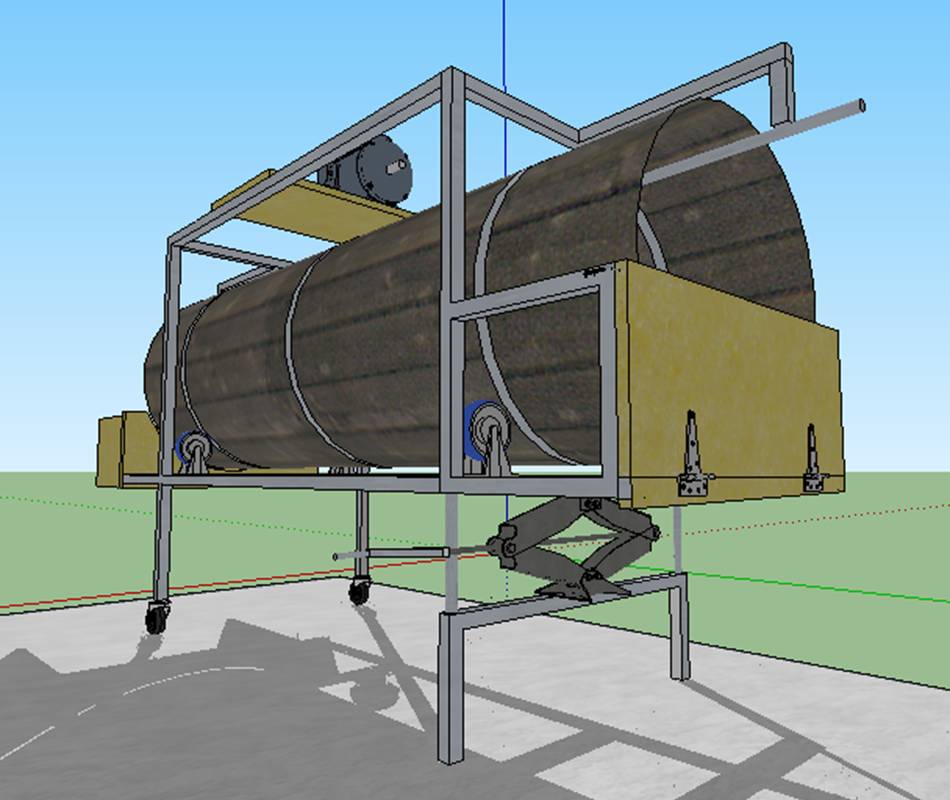

Sketchup diagrams Version 1 is when I was going to use the "standard" chain drive with the motor on top seen on many other root washers. I want a door on one end and a shoot on the other. I also plan to add a scissor jack under one end to adjust the level/pitch of the barrel, with castors on the other legs.

Version 2 shows some of the changes I have made to the frame to incorporate the bigger drive wheels (12" pneumatic tires).

Bill of materials and Sourcing Most of the frame is made from 1" box steel I sourced locally 4 x 5/8" pillow blocks 2 x 5'x5/8" axle 4 x 12" pneumatic tires (with 5/8" hole) roller chain 2 big chain pulleys (do not exceed width of drive wheels) antique reduction gear box (mine is about 30:1) antique motor (I think mine is 3600rpm, but it doesn't say, and I haven't done the math) couple of casters 6' x 3/4" copper pipe scrap wood odds and ends around the shop

Construction/how to build -I started by putting the frame together as seen in the pics. -Then drilled some holes and attached the pillow blocks with bolts. -Put the axle, wheels, and chain sprockets on -Test drove with rain barrel -Add the motor (originally a garage door opener), and chain -Built the barrel with 1x4s and 3 equal sized old bike rims -Soldered some fittings on the 3/4 copper pipe, drilled some strategically placed holes -Fitted that in the barrel with some rebar I accidentalyl mowed -Added a shoot at the front -Added a door at the back

Next steps/goals/barriers Next summer I want to find bigger bike rims to build a bigger barrel

Hope this root washer would be really very beneficial for the organic vegetable farms and would sort out most of the problem of the farmers they were facing since long.

I'm interested in this.

You started building design version #2 on 08/21/13. Where are the links to pics & plans, and discussion of how the prototype has worked out in trials?

Hey Joel, thanks for your interest in this, you have to remember that 08/21/13 is a busy time for farmers in the north, I was hoping for some feedback on the design before I started cutting and welding. Something like the gears on a garage door opener will never hold up or garage door openers aren't suitable for continuous use (see post below).

Well things are finally slower and I thought I would give a little update on this project. The garage door opener didn't work. The motor is not rated for continuous use and would quickly overheat if I ran the motor constantly. I then bought an old electric motor from the local antique dealer, and attached that to the gearbox of the garage door opener. This worked well for a while, but the plastic gears from the garage door opener eventually gave out, and I was once again in need of a new fix. I went back to the same antique dealer as before I had eyed up what looked like a worm gear. I once again remade the mounting brackets for the motor/gearbox, covered it all with a bucket and it worked beautifully, this fall we washed a several thousand pounds of carrots, beets, parsnips, potatoes, turnips and rutabagas. I have a bunch of pics I will use to document this build as time permits.

Could you post your sketchup files to the 3d warehouse? I would be happy to add them to the Farm Hack collection already started.

I have never done this before but I uploaded them to the 3D warehouse, you can find them by searching for "Barrel Wahser". Yes please feel free to add them to the Farm Hack collection.

Thanks for posting. These are super helpful. Once they are posted we can also embed the models in our posts and use them for future tool postings.

The farmhack collection of other sketchup models is here http://sketchup.google.com/3dwarehouse/cldetails?mid=cc34dd5b3d6df3291e32d9fc07262782&ct=mdcc

Did you by any chance photograph the fabrication stages? (a la Instructables.com)

Due to possible accommodations and alterations along the path of actually going from plan to genuine prototype, it'd be great if people did that (photo'd and posted) here. Just a suggestion. :)