Cover Crop Roller

Primary tabs

Problem addressed/functional need

This tool is designed to increase organic matter in soil, retain moisture, reduce cultivating passes and herbicide use. It functions by stressing the annual cover crop at the vulnerable point between when the plant puts energy into producing seed, but before it produces viable seed. Because the covercrop is not cut, it does not resprout, and because it stays rooted, it does not bunch or blow away after it starts to dry...

This tool was developed by Rodale Institute and make opensource on its web site here http://www.rodaleinstitute.org/notill_plans, and more information can be found on their web site http://www.rodaleinstitute.org/introducing_a_cover_crop_roller, and at GreenStart's web site http://www.greenstartnh.org/index.php?option=com_content&view=article&id=52&Itemid=73

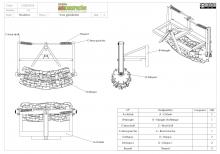

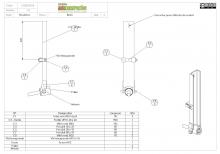

A recent improvement to address the functionality in less than flat field conditions was developed and released by http://www.adabio-autoconstruction.org/outils/tous-les-outils/rouleau-faca-pour-buttes.html

Plans are available here http://www.adabio-autoconstruction.org/IMG/pdf/faca.pdf The following shows a sketchup drawing of the improved roller

The following is a video of the improvement in action

Rouleau FACA pour buttes by Adabio_Autoconstruction

Functional Description/approach <strong/>

The following are some tips to make it work better.

Field Preparation • Level field prior to cover crop seeding • Uneven fields will result in poor cover crop kill - unless using the flexible model developed by ADABIO • Roller-crimper will kill cover crops on rises and miss crops in dips- unless using the flexible model developed by ADABIO • Soil test and amend soil to make sure there are no nutrient deficiencies to ensure a healthy covercrop with sufficient biomass

Cover Crop Selection • Winter rye (cereal rye) is most common • ‘Aroostook’ rye will establish later and mature earlier • Hairy vetch & Austrian winter pea also commonly used often mixed with a cereal grain such as winter rye • Winter rye with crimson clover may also work (crimson may winterkill) • Plan cover crop based on nitrogen needs of cash crop (C:N ratio) • Mix cover crops that will mature/flower at same time (Austrian Winter Pea and Winter Rye)

Cover Crop Establishment • Use high rates (typically 150% of typical rate) • Plant earlier in the fall to obtain maximum biomass • Drilling and broadcasting often give maximum coverage • Drill in the opposite direction you will plant

Cover Crop Termination • Assure your cimper has enough down pressure • Crimp when 75% of crop is in full flower • Goal is to crimp – not cut – the stem • It’s ok to crimp twice – it may be needed • One pass crimping & planting is not necessary

Other equipment may be used to roll or crimp • Light disc without offset or a no-till drill can work in some conditions • Disengaged flail mower

Cover crop should be weed free and thick after rolling (at least 3 Inch thick w/no gaps; should not see soil)

No-Till Planting • Soil tends to be not as wet in spring • Can get on field earlier; BUT • Soil temperature may be cooler under mulch • Works best with transplants and large seeds or vigorous growers. Sorghum Sudan grass planted into standing winter rye which was then crimped has also worked well. • Planter will need extra weight if planting through the rolled mulch, or consider planting into the standing crop and roll after planting • Plan to test and use aggressive residue management (row cleaners) • In-row fertilization will increase success • there may be some Nitrogen tie-up with high carbon cover crops • Phosphorus tie-up is also possible in cold soils

There are several alternative approaches which use the same principles. One in particular was developed by Charles Martin & Family in Loysville, PA. It uses crimpers mounted directly on the no-till planter which have adjustable pressure and float independently from each other to follow the ground. The independent action avoids one of the short comings of the larger crimpers of the Rodale design, which when hitting a high or low spot will not evenly crimp along the whole length.

Here is video of the corn planter integrated with floating in-row roller crimpers

** Bill of materials and Sourcing **

this section should include a list of materials, and dimensions and sources for each item when available)

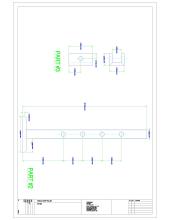

Construction/how to build see plans in photo section

Next steps/goals/barriers

ADABIO's approach improves the design to address issues with ground contact in rougher field conditions, greater weight transfer from tractor to the roller would be helpful easier transport improve planter function through the rolled mulch alternate cover crop and planter setup or plant/crimp order strategies need to be refined

Further - Documentation of construction techniques

This section is to highlight what next steps are needed for documentation or construction to move the project along. This might contain a link to a kickstarter campaign or to a forum discussion of documentation or prototype needs etc.

Marketplace

This tool is currently being manufactured by I&J manufacturing http://www.croproller.com/